Home > Company Introduction

Company Overview

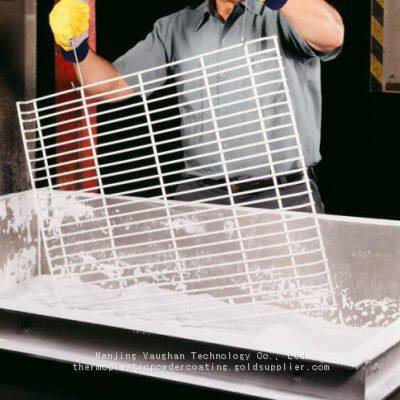

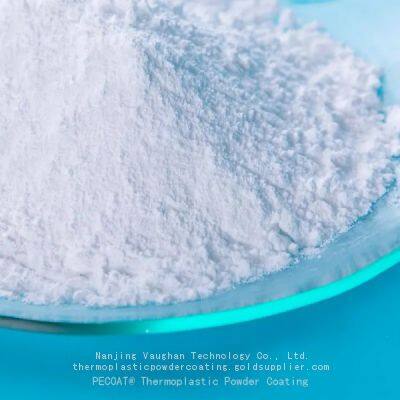

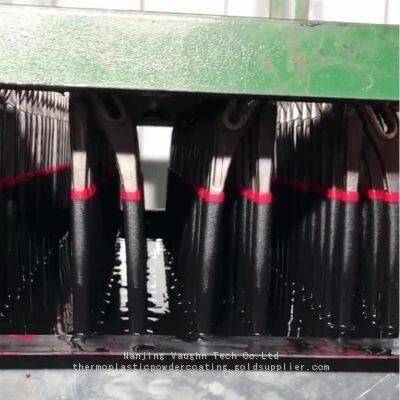

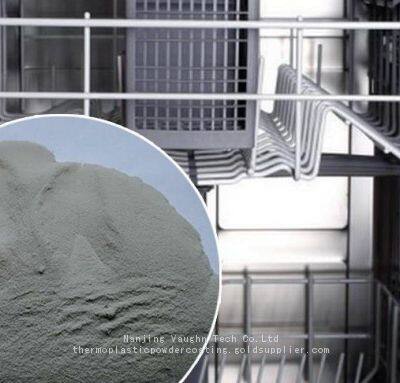

Our company is committed to research, develop, productioin and export of thermoplastic polymer, thermoplastic powder coatings, pvc plastisol liquid coatings and supporting thermoplastic dip coating equipment. We strives for excellence in product performance and quality. From raw materials entering the warehouse to product bagging and warehousing, every process is carefully inspected, realizing full control of the product quality and ensuring the stability and consistency of the product quality. 【POLYMER BRANCH】 takes pride in having experienced senior technicians and production workers who ensure the high quality of itsproducts. The company offers a diverse range of thermoplastic coatings, including polyethylene powder coating, polypropylene powder coating, Pvc powdelcoating, PVc plastisol coating, and nylon powder coating.【 MACHINERY BRANCH】is an essential branch factory, plaving a crucial role in the overall production ecosystem. The factory production workshop covers an area of 10,000 square meters, providing ample space for efficient and streamlined manufacturing processes.

-

ManufacturerBusiness Type

-

2018Year Established

-

5,000-10,000 square metersFactory Size

-

US$2.5 Million - US$5 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

11 - 50 People Total Employees

-

1-10 People Sales Staff

-

5-10 People Quality Inspectors

-

HACCP, TL900, QS9000, SA8000, ISO9001, ISO9004, ISO17799, ISO9000, ISO14000, ISO10441, ISO16949, TS16969, ISO19011:2000, OHSAS18001, Others Product Certifications

-

US$2.5 Million - US$5 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Shanghai, Ningbo, Tianjin, Qingdao Port of Shipment

-

Building Coating Main Industry

-

Quality Control【POLYMER BRANCH】 In the raw material phase, comprehensive incoming inspections are conducted on core raw materials such as resins, pigments, and additives. Component purity is verified through infrared spectroscopy analysis, and powder particle size uniformity is ensured using a particle size distribution analyzer. During the production process, a real-time online monitoring system is activated, with sampling tests for melt flow index and color stability conducted every 15 minutes. Key parameters such as melt mixing temperature and extrusion pressure are dynamically adjusted. Finished products must pass over 10 tests, including salt spray resistance , impact resistance , and adhesion. 【MACHINERY BRANCH】Core components such as heating tubes and equipment bodies are made of 304 stainless steel. Upon incoming inspection, they must pass over 20 tests, including strength and pressure resistance (1.2 times the rated pressure) and precision calibration (tolerance ≤ 0.05mm). The "Three-Inspection System" (self-inspection, mutual inspection, and special inspection) is implemented during assembly.

Quality Control【POLYMER BRANCH】 In the raw material phase, comprehensive incoming inspections are conducted on core raw materials such as resins, pigments, and additives. Component purity is verified through infrared spectroscopy analysis, and powder particle size uniformity is ensured using a particle size distribution analyzer. During the production process, a real-time online monitoring system is activated, with sampling tests for melt flow index and color stability conducted every 15 minutes. Key parameters such as melt mixing temperature and extrusion pressure are dynamically adjusted. Finished products must pass over 10 tests, including salt spray resistance , impact resistance , and adhesion. 【MACHINERY BRANCH】Core components such as heating tubes and equipment bodies are made of 304 stainless steel. Upon incoming inspection, they must pass over 20 tests, including strength and pressure resistance (1.2 times the rated pressure) and precision calibration (tolerance ≤ 0.05mm). The "Three-Inspection System" (self-inspection, mutual inspection, and special inspection) is implemented during assembly. -

Our ServicesProduction and export of thermoplastic coatings and thermoplastic dip coating equipment. Thermoplastic coatings include polyethylene powder coating, pvc powder coating, polyamide PA nylon powder coating, pvc plastisol coatings. Thermoplastic Dip coating equipment includes fluidized bed dip powder coating line, pvc dip coating line, pvc dip mould machine, greenhouse wiggle wire plastic coating making equipment.

Our ServicesProduction and export of thermoplastic coatings and thermoplastic dip coating equipment. Thermoplastic coatings include polyethylene powder coating, pvc powder coating, polyamide PA nylon powder coating, pvc plastisol coatings. Thermoplastic Dip coating equipment includes fluidized bed dip powder coating line, pvc dip coating line, pvc dip mould machine, greenhouse wiggle wire plastic coating making equipment. -

Our TeamCore business operations consist of two major professional divisions: 【POLYMER BRANCH】 (Thermoplastic Coating Division) and 【MACHINERY BRANCH】 ( Thermoplastic Dip Coating Equipment Division). These two divisions perform their respective duties, relying on professional technology and rigorous processes to jointly ensure product quality and technical service standards.

Our TeamCore business operations consist of two major professional divisions: 【POLYMER BRANCH】 (Thermoplastic Coating Division) and 【MACHINERY BRANCH】 ( Thermoplastic Dip Coating Equipment Division). These two divisions perform their respective duties, relying on professional technology and rigorous processes to jointly ensure product quality and technical service standards.